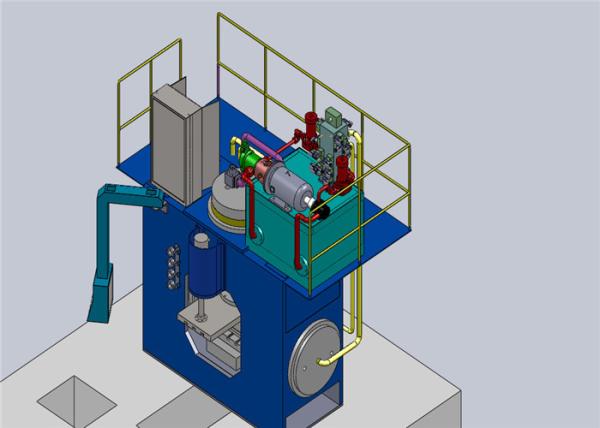

Manufacturing for pipe installation diameter 219 inch carbon steel

stainless steel tee cold push tee machine

Tee forming machine technology is to use the tube blank as the raw

material, by applying the liquid pressure in the tube cavity and

applying the load in the axial direction, make it plastic

deformation in the mold cavity, the tube wall and the inner surface

of the mold, so as to obtain the forming technology of the required

shape parts.Difficult for small size of fillet, molding products

tend to adopt sectional pressure forming,namely first complete the

expansion pipe, with smaller pressure line into a large rounded

corners, have maintained uniform wall thickness at this time, then

the pressure increase, forcing fittings mold joint, the rounded

materials tensile deformation, the tube wall thinning, finally get

the tee. Forming principle of three-way forming machine: first, put

the tube blank into the lower die cavity, press the plunger push

head into both ends of the pipe fitting under the action of

hydraulic cylinder, so that the pipe fitting cavity is sealed, and

then inject the liquid medium into the pipe fitting cavity through

the liquid channel in the push head;At this point, the upper mold

moves downward, forming a closed mold cavity together with the

lower mold. Finally, the pressure of high-pressure pump and valve

control liquid increases continuously, and the push head pushes the

pipe fitting inward. The pipe wall deforms and gradually sticks to

the inner wall of the mold, forming the tee.

| Specification | Unit | HYT-315 | HYT-500 | HYT-1000 | HYT-1500 | HYT-2000 | HYT-4000 |

| Tee OD range | lnch | 1~4 | 3~6 | 4~8 | 8~12 | 10~16 | 20~28 |

Master

cylinder | Normal force | KN | 3150 | 5000 | 10000 | 15000 | 20000 | 40000 |

| Work stroke | mm | 450 | 480 | 610 | 670 | 800 | 1200 |

| Go down speed | mm/s | 60 | 80 | 80 | 80 | 80 | 80 |

| Work forward speed | mm/s | 8~12 | 8~12 | 8~12 | 8~12 | 8~12 | 8~12 |

| Return stroke speed | mm/s | 80 | 100 | 100 | 100 | 100 | 100 |

Side

cylinder | Normal force | KN | 3150 | 5000 | 8000 | 12500 | 18000 | 40000 |

| Work stroke | mm | 300 | 320 | 340 | 360 | 410 | 500 |

| Advance speed | mm/s | 10~15 | 10~15 | 10~15 | 10~15 | 10~15 | 10~15 |

| Return stroke speed | mm/s | 60 | 60 | 60 | 60 | 60 | 60 |

Push-out

cylinder | Normal force | KN | 300 | 400 | 500 | 630 | 1500 | 2000 |

| Work stroke | mm | 300 | 300 | 400 | 450 | 550 | 700 |

Workbench

effective area | Right and left | mm | 550 | 750 | 900 | 1200 | 1400 | 1800 |

| Front and back | mm | 400 | 580 | 800 | 1000 | 1200 | 1500 |

| The max distance from slide block to workbench | mm | 190 | 250 | 370 | 460 | 520 | 650 |

| Center high of side cylinder | mm | 980 | 1100 | 1350 | 1800 | 1900 | 2500 |

| Motor power | KW | 30 | 45 | 74 | 110 | 220 | 330 |

Application:

It can apply for making stainless steel tee, carbon steel tee,

Features:

1. Hydraulic Tee Forming Press/tee making machine has rigid

construction assures highly reliable operation.

2. Adopt Germany technology.

2. Special hydraulic circuit design improve working efficiency.

3. High efficiency and low noise hydraulic system can save energy

and improve working environment.

4. User-friendly touch-screen panel provides easy operation and

trouble-shooting.

5. The Safety inter-lock device assures perfect operator safety.