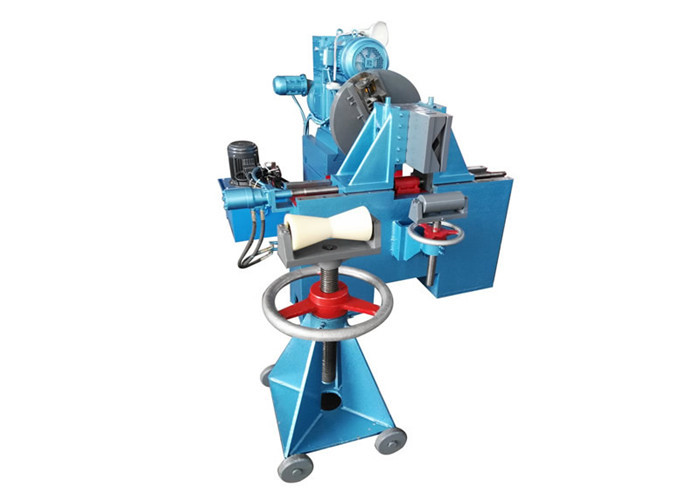

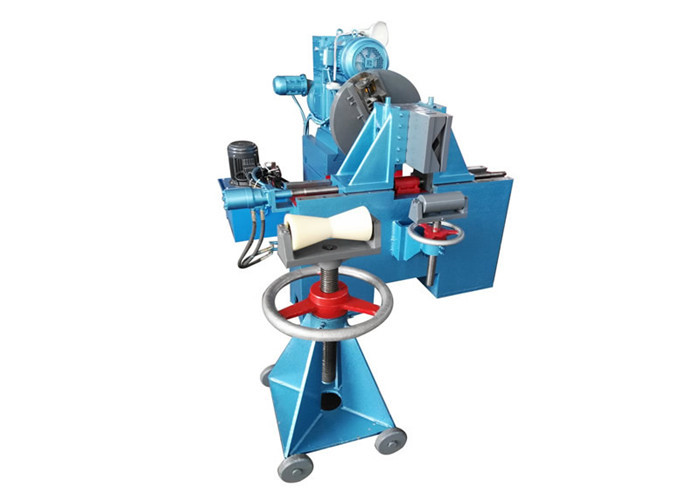

Φ50-Φ425 Q1245 Shean Hydraulic Electric Pipe Beveling Machine

Q1245 hydraulic electric groove machine is absorbing the advantages

of various kinds of pipe groove machine production and the users

need to design, suitable for 50 - Φ Φ 425 mm diameter and wall

thickness of 6-100 - mm seamless steel tube pipe groove processing.

This machine use standard power head restructuring has strong

cutting ability and special power differential radial feed box,

workpiece clamping using manual clamping device, also can use power

box host about manual adjustment and v-shaped holder to work

manually, adjust the up and down looking for are: pipe cutting

groove Angle head differential automatic feed used for machining,

when the pipe wall thickness is less than 12 mm also can be used in

a human hand mobile host with forming cutter cutting forming at a

time.

The machine is equipped with additional brackets and rolling

brackets. The pipe can be adjusted up and down to meet the

requirements of the center of various specifications of the steel

pipe and the bevel machine. The rise and fall of the supporting

roller on the brackets are manually operated.

The machine is safe, reliable, convenient and applicable to a wide

range of pipe end groove processing equipment.

| Parameter/model | YQ-89 | YQ-168 | YQ-325 | YQ-630 | YQ-820 | YQ-1020 | YQ-1800 |

| Turning diameter(mm) | 21-89 | 89-168 | 168-325 | 325-630 | 630-820 | 820-1020 | 1020-1800 |

| Revolution of cutter head(rpm) | 600 | 350 | 200 | 150 | 100 | 80 | 40 |

| Feeding turn volume(mm/r) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

1) The company's pipe end beveling machine is currently the most

advanced end beveling machine in China, with both radial and axial

feeding functions, is a combination of radial end beveling machine

and axial end beveling machine;

2) The tool used is standard tool, which can meet the requirements

of v-shaped, double-v-shaped, u-shaped and i-shaped groove

processing, no need to customize molding tool, convenient and

quick. In the market, when using other machine to bevel double V, U

groove, need to replace another homemade molding tool that will

increase production labor, high cost, and low efficiency, and poor

operability.

3) For pipes with ordinary wall thickness, axial feed function is

adopted to complete high-speed groove; for pipes with thick wall

thickness or compound groove of double V type and U type, radial

feed function is adopted to complete compound groove processing

without changing blades.

4) General Performace:

Meet the "quality and efficiency" principle.

With high precision, high stiffness, high efficiency, high degree

of automation, high reliability.

After a long period of continuous use of precision maintenance

ability to adapt to the environment, can quickly form the

production capacity.

The groove has the function of radial and axial feed, and the

technology is advanced.

Greatly improve the efficiency and precision of pipe groove

processing.

The equipment has independent intellectual property rights.