hot induction pipe expanding machine for expansive small pipes

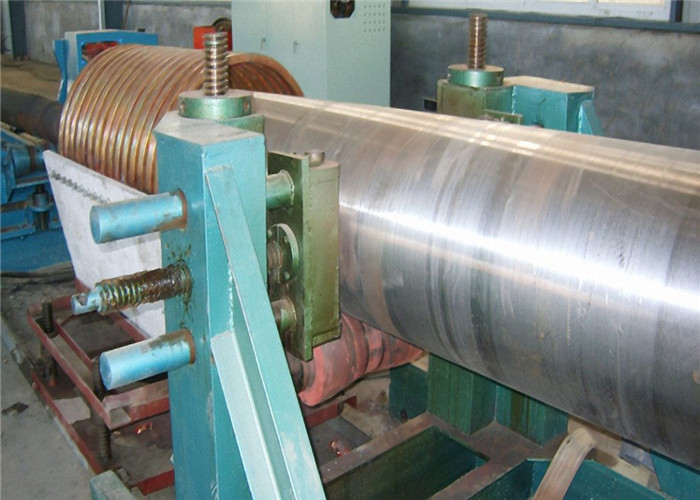

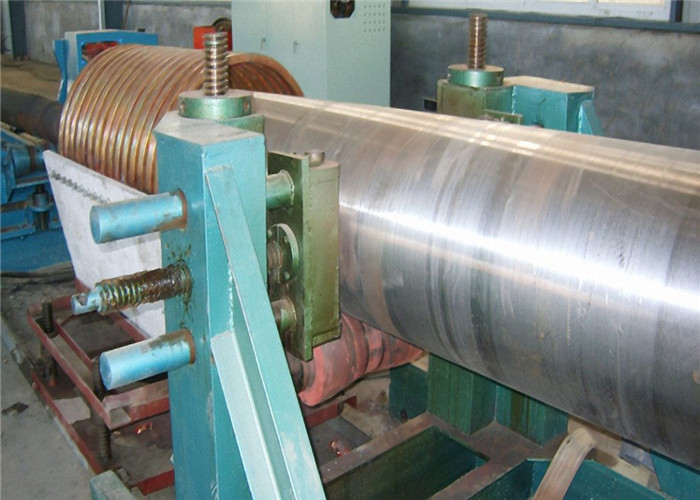

The main components of the tube expanding machine include: stand,

main oil cylinder support plate, movable push plate,front support

plate, automatic feeding mechanism, discharging roller table, mold

support, intermediate frequency coil adjusting frame, (including

intermediate frequency heating coil) intermediate frequency power

supply, electrical control system.

Operating process of the expanding machine: the rinsed pipe is sent

to the rotary idler device on the center line of the expanding

machine.Using this rotating idler device, combined with the camera

system, the tube weld is precisely rotated to the 12 o 'clock

position to ensure that the weld can enter the groove of the upper

sector of the tool during subsequent diameter enlargement.The

lifting cone roller way lifts the pipe to the center line of the

reaming machine and the position is controlled by the displacement

sensor in the lifting hydraulic cylinder.The clamping trolley moves

forward and is controlled by a metal detector to detect the end of

the tube and to secure it. At the same time, a signal is sent to

start the feeding roller of the clamping trolley. The position is

controlled by an encoder.The pipe length is combined with the

reaming head to automatically calculate the optimal reaming

steps.The clamp jaws can be rotated to avoid damaging the tube

wall.During the advance, the height of the clamp can be adjusted to

compensate for the pipe straightening deviation and optimize the

straightening effect of the reamer.

| NO. | Model | Finished pipe

ranges(mm) | Thrust(t) | Max working feed

speed (mm/min) | Return speed

(mm/min) | M.F power(kw) | Max working

thrust(t) | Mother pipe

length(mm) | Max wall thickness of finished pipe(mm) |

| 1 | HY-219 | 89-219 | 84 | 2200 | 6500 | 200-250 | 72 | ≤24000 | 30 |

| 2 | HY-325 | 168-325 | 106 | 1700 | 5000 | 250-300 | 91 | ≤24000 | 40 |

| 3 | HY-426 | 219-426 | 160 | 1600 | 4500 | 350-400 | 137 | ≤24000 | 50 |

| 4 | HY-530 | 273-530 | 206 | 1250 | 3500 | 400-450 | 177 | ≤24000 | 60 |

| 5 | HY-630 | 325-630 | 260 | 1200 | 3200 | 450-500 | 220 | ≤24000 | 80 |

| 6 | HY-720 | 355-720 | 300 | 1200 | 2300 | 500-600 | 257 | ≤24000 | 100 |

| 7 | HY-820 | 426-820 | 300 | 1200 | 2200 | 600-800 | 257 | ≤24000 | 100 |

| 8 | HY-914 | 457-914 | 330 | 1000 | 1800 | 600-800 | 282 | ≤24000 | 100 |

| 9 | HY-1020 | 530-1020 | 510 | 900 | 1600 | 800-1000 | 437 | ≤24000 | 120 |

| 10 | HY-1220 | 630-1220 | 670 | 800 | 1600 | 800-1000 | 574 | ≤24000 | 120 |

| 11 | HY-1420 | 720-1420 | 850 | 740 | 1400 | 1000-1200 | 728 | ≤24000 | 150 |

By the core technology of the patent-Steel Tube OD Hot Expansion,

the requirements of different kinds of pipe diameters are

satisfied,especially the large diameter pipes and kinds of

non-standard steel pipes with different diameters , and some small

batch steel pipe with various specifications. It is the main

production technology to produce large outside diameter steel pipe,

high pressure steam piping of power station and nuclear power plant

. The expanded pipes has been widely used in the fields of military

industry, aerospace industry and marine industry equipment

manufacturing, which has made a great contribution to national

defense and energy construction.

The equipment is used in the diameter expanding production of

seamless pipe, straight welded pipe, spiral welded pipe etc.The

suitable material for expansion includes: plain carbon steel, kinds

of alloy steel and stainless steel.